One of the problems no one wants to encounter is blown out sparkplugs. Eric has the ability to repair the damaged threads with the head still on the vehicle. His expertise at repairing this particular problem has earned him many regular, satisfied customers.

The Problem:

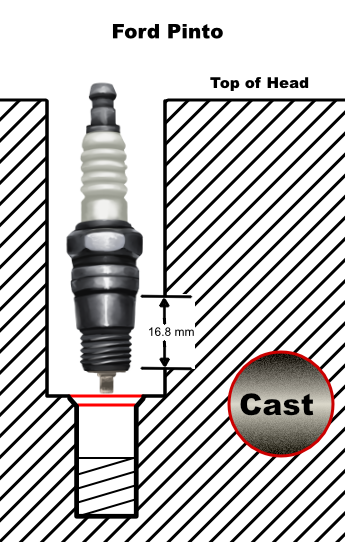

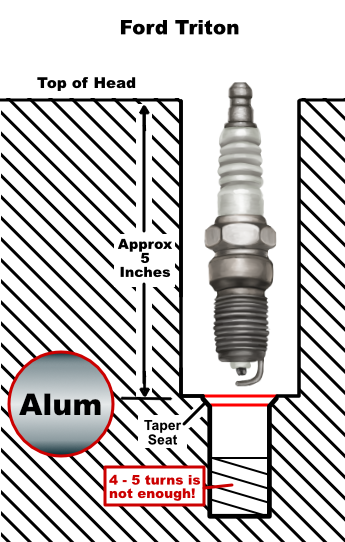

The Ford Pinto has a Cast Iron head, this works great! There was no chance for cross threading.However, the Ford Triton changed to an Aluminum head and a redesigned, full thread, sparkplug. With these changes the hole in the head remained the same and was not fixed to accommodate the new sparkplug. This means that there is ONLY 4-5 turns of aluminum to hold the sparkplug in.

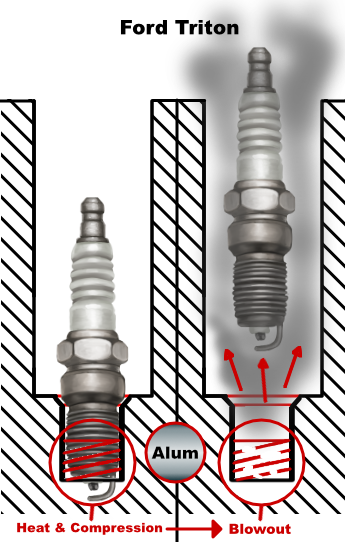

What this leads to:

The aluminum head faces compression and heat and over time which fatigues and weakens the aluminum causing the already low amount of hold that the 4-5 turns of aluminum gives to the sparkplug to give way under the pressure. This tears out the aluminum threads resulting in:Sparkplug Blowout!!!

But have no fear! Eric’s Laz-R-Out specializes in the on site and on vehicle repair of blown out sparkplug threads, eliminating the necessity of removing the heads from the vehicle.Repair:

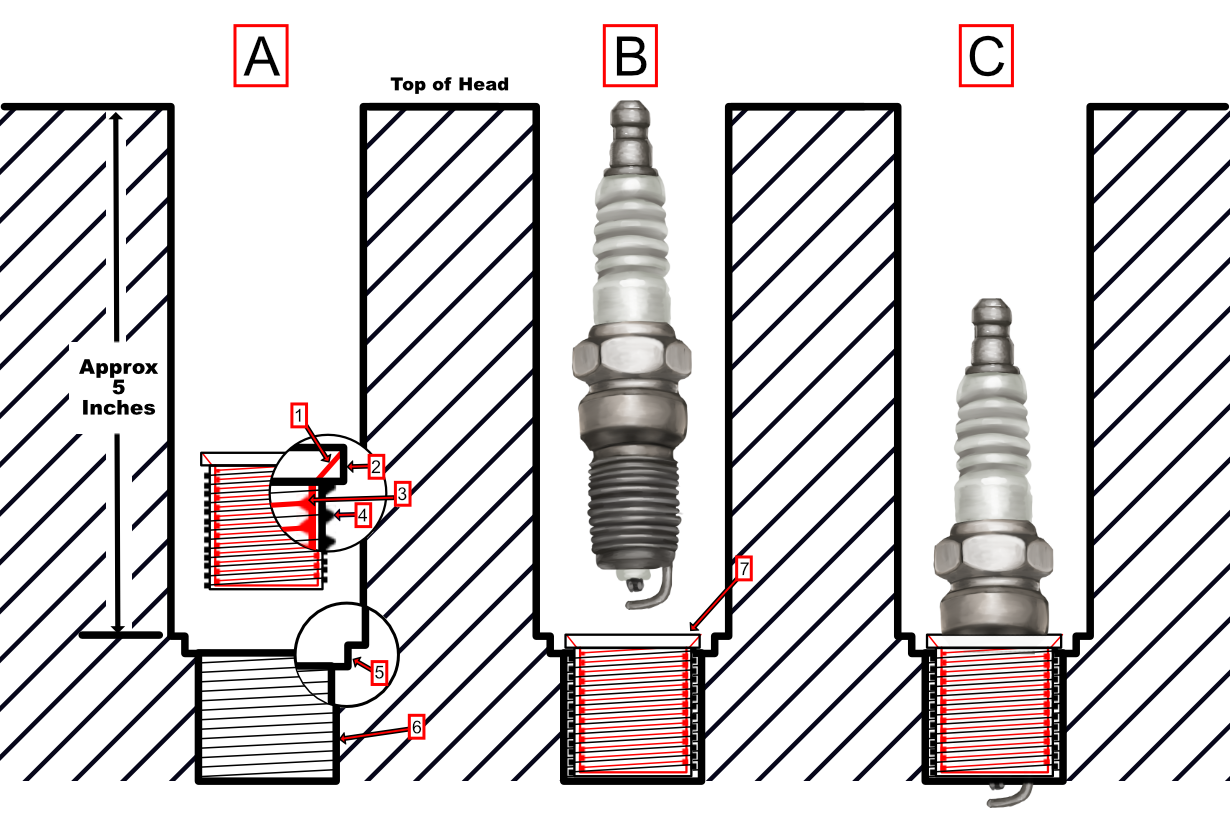

| A | B | C |

|---|---|---|

| To repair, the sparkplug hole must be threaded oversized and then an insert is installed. This presents a challenge on the Triton engine due to the depth of the sparkplug counter bore hole. It is approximately five inches deep to the seat. | The head is now fully threaded oversized for the standard thread insert (STI). The new tapered seat insert is installed and now accepts full threaded sparkplug designs only! | Your newly installed insert is stronger than the factory design and eliminates sparkplug blowout. The repair should last the life of the vehicle. Remember, Eric’s Laz-R-Out specializes in the on site repair and installation of inserts WITHOUT REMOVING THE HEAD!!! |

A

To repair the sparkplug hole it must be threaded oversized and then an insert is installed. This presents a challenge on the Triton engine due to the depth of the sparkplug counter bore hole. It is approximately five inches deep to the seat.B

The head is now fully threaded to the standard thread insert (STI) oversized and the new tapered seat insert is installed, this accepts full threaded sparkplug designs only!C

Your newly installed insert is stronger than the factory design and eliminates sparkplug blowout. The repair should last the life of the vehicle. Remember, Eric’s Laz-R-Out specializes in the on site repair and installation of inserts WITHOUT REMOVING THE HEAD!!!

Insert specifications:

(See illustration above)

- Internal Taper Seat, illustrated in red (See A)

- External Square Corner (See A)

- Internal Thread 14x1.25, illustrated in red (See A)

- External Thread 14x1.25 S.T.I. oversize (See A)

- Square seat cut for insert (See A)

- S.T.I oversized hole (See A)

- Insert installed into S.T.I. oversized hole. Internal thread will now accept full thread length sparkplug design. (See B)